RUTILE TITANIUM DIOXIDE (TiO2)

Rutile titanium dioxide is widely applied today in modern industry:

Varnish, enamel, paint and associated coatings: titanium dioxide is used for bleaching, covering power improvement, surface protection against ultraviolet rays, film lasting enhancement and prevention from yellowing of coated surface;

Varnish, enamel, paint and associated coatings: titanium dioxide is used for bleaching, covering power improvement, surface protection against ultraviolet rays, film lasting enhancement and prevention from yellowing of coated surface; Paper and paperboard: titanium dioxide is used as a main means of bleaching and paper stock covering power improvement, as well as applied in paper binder production.

Paper and paperboard: titanium dioxide is used as a main means of bleaching and paper stock covering power improvement, as well as applied in paper binder production.

Synthetic fiber/fabric: titanium dioxide is also used for twisted fiber delustering.

Plastics (e.g. window frame, garden furniture, household accessories, plastic parts for automotive industry): titanium dioxide is used to ensure high level of whiteness and color saturation, to avoid surface ageing and yellowing, as well as to improve plastic resistibility.

Titanium dioxide is the main colorant in enamel production industry due to its highest degree of whiteness. It has been applied in paintwork materials production since 1916 and nowadays more than 50% of titanium dioxide produced in the world is applied in paint industry, 19% is used for production of plastics and 17% - for paper production.

Titanium dioxide has a number of advantages as compared to zinc-based and lead-based colorants: inertness, nontoxicity, versatility, dispersive ability, high degree of whiteness, high covering power, etc. Due to these advantages titanium dioxide is still considered to be the most effective and universal white colorant of the global industry.

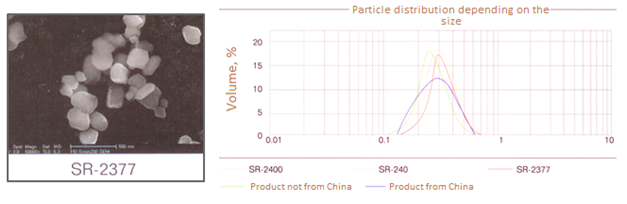

GRADE SR 2377

SR 2377 grade is a rutile pigmentary titanium dioxide produced using chloride technology and having a surface, treated by aluminum and zirconium oxides for wider application range.

Field of application:

|

Advantades:

|

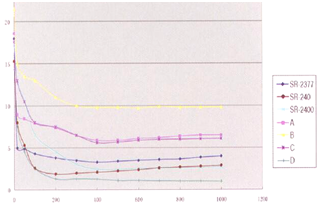

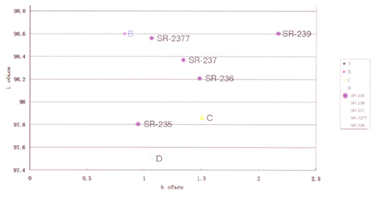

Process performance

Process performance

With the actual speed and temperature parameter and under the consolidating force, 50% of titanium dioxide and 25% of calcium carbonate interfuse forming high-quality product.

Note:

A, B – Chinese product;

C, D – Well-known product.

Thawing index

Under a certain temperature and pressure titanium dioxide thawing index can be tested. Titanium dioxide, calcium carbonate and polyethylene mix together in ratio 50:25:25. The test is carried out under 190°C temperature and 5 kg load.

| No. | Product | Temperature | Result g/10 min | Test under pressure |

| 1 | SR-2377 | 190˚C | 5 кг | 14.9 |

| 2 | SR-240 | 190˚C | 5 кг | 12.9 |

| 3 | SR-2400 | 190˚C | 5 кг | 22.1 |

| 4 | А | 190˚C | 5 кг | 12.3 |

| 5 | В | 190˚C | 5 кг | 11.5 |

| 6 | С | 190˚C | 5 кг | 23.1 |

| 7 | D | 190˚C | 5 кг | 21.6 |

Note:

A, B – Chinese product;

C, D – Well-known product.

Specifications:

| PERFORMANCE | |

| Titanium dioxide content, % | > 94 |

| Rutile content, % | ≥98 |

| Inorganic coating | Zirconium, Aluminum |

| Crystal size, µm | 0,3 |

| Unit weight, g/cm3 | 4,0 |

| Water consumption, cm3/ 100g of colorant | 26 |

| Oil absorption, g/100g | 18~22 |

| Density, g/cm3 | 1,1 |

| Color under CIEL | ≥97.5 |

| Water extract рН level | 7,0~9,0 |

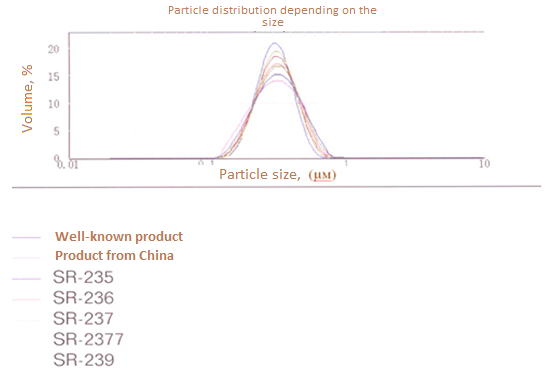

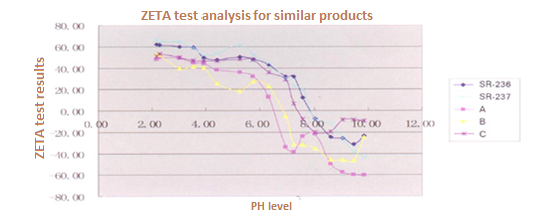

GRADE SR 237

SR 237 grade is a high-quality rutile titanium dioxide produced using chloride technology and having a surface, treated by modified aluminum. This material is designed to be applied in emulsion paint, powder coating and paper production.

Note:

A, B – Chinese product;

C, D – Well-known product.

Color comparison:

Color comparison:

Paint formula test (25% as part of general formula of two-component polyurethane paint)

| Tested samples | Well-known product | SR-237 | SR-2377 | SR-236 |

| Color L*(CIELAB) | 98,31 | 98,16 | 98,26 | 98,13 |

| Color а*(CIELAB) | -0,81 | -0,43 | -0,32 | -0,53 |

| Color b*(CIELAB) | 1,38 | 1,36 | 1,23 | 1,46 |

| Color c*(CIELAB): | 1,60 | 1,76 | 1,76 | 1,83 |

| Color h*(CIELAB): | 120,46 | 113,26 | 118,26 | 116,26 |

| Nontransparency | 79,11 | 77,61 | 79,01 | 78,11 |

| Contrast range | 86,89 | 85,68 | 86,38 | 85,78 |

| Luster | 7,00 | 7,00 | 7,00 | 7,00 |

Specifications:

| PERFORMANCE | |

| Titanium dioxide content, % | > 93 |

| Rutile content, % | ≥98 |

| Inorganic coating | Aluminum, silica |

| Crystal size, µm | 0,29 |

| Unit weight, g/cm3 | 4,0 |

| Water consumption, cm3/ 100g of colorant | 30 |

| Oil absorption, g/100g | 18~21 |

| Density, g/cm3 | 1,0 |

| Color under CIEL | ≥97.5 |

| Water extract рН level | 7,0~8,5 |

Application:

| FIELD OF APPLICATION | GRADE SR-237 | GRADE SR-2377 | ||

| Water-based paint | ||||

| Interior works | Ö | Ö | ||

| External works | Ö | Ö | ||

| Solvent-based paint | ||||

| Interior works | - | Ö | ||

| External works | - | Ö | ||

| Automotive paints | ||||

| Electric precipitation | - | Ö | ||

| Finishing coat | Ö | Ö | ||

| Refreshment works | - | Ö | ||

| Metallic paints | Ö | - | ||

| Synthetic resin-based paints | ||||

| Interior works | Ö | - | ||

| External works | Ö | - | ||

| Emulsion paints | ||||

| High covering power | - | Ö | ||

| Gloss | - | Ö | ||

| Other | ||||

| Powder coating | Ö | Ö | ||

| Coating for tin package | - | Ö | ||

| Coating for bobbins | Ö | Ö | ||

| Coating for sea vessels | - | Ö | ||

| Coating for wood | - | Ö | ||